Product series

Introduction of BSM self-healing impermeability agent

Why can BSM self-healing impermeability solve durability problem?

International Structural Concrete Institute (FIB)

Through the tests and experiments of multinational authorities and experts, the conclusions are drawn:

At present, it is the most effective and economical concrete anti-seepage additive that can withstand high static water pressure in the world

As a real concrete impermeability additive product

BSM products not only improve the impermeability of concrete under high hydrostatic pressure, but also provide comprehensive protection against chemical attacks, freeze-thaw cycles, oxygen ion penetration and other problems。The addition of BSM (electric flux less than 1000C, life of more than 100 years) to concrete batching can significantly improve the durability and service life of concrete。

What are the advantages of BSM self-healing impermeability?

BSM's leading technical performance

It is a product of "new cement-based osmotic crystallization"

The BSM self-healing impermeable agent is a "new cement-based osmotic crystallization" product, which is easy to construct and is not affected by climatic conditions. It is added to the concrete matrix and becomes an integral part of the structure, which continues to play a role during the life of the concrete。Continuous testing and improvement ensures that BSM gives concrete lasting and effective protection even in the harshest environments。

The working principle of BSM self-healing impermeability

The working principle of BSM self-healing impermeability

Anhydrous dormancy in case of water crystallization repeated cycle lifetime self-healing

|

Realize self-healing function of matrix As water further penetrates into the concrete structure, it reacts with the above-mentioned hydration potential substances and unhydrated cement to accelerate the formation of crystal precipitation The microcracks and other defects in cement-based materials are compacted by gluing, which realizes the self-healing function of the matrix and plays a waterproof role。

|

|

|

The active substance becomes a free radical again It continues to migrate inside the concrete structure with water seepage。

|

|

|

The process repeats itself The impermeability of the structure;When the structure is in a dry state, the active substance is in a dormant state due to the lack of diffusion medium such as water. Once water seeps through the body, the active substance is activated and continues to react to form new crystals。

|

|

Analysis of three core technologies of BSM

|

|

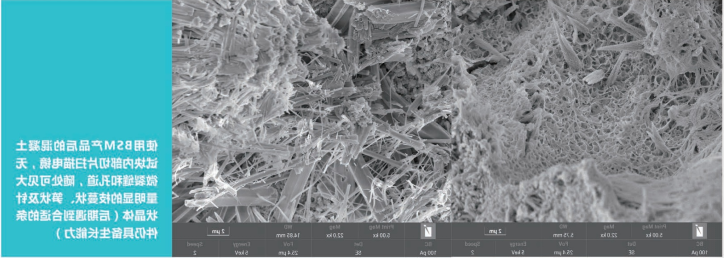

| Super strong catalytic crystallization bonding technology BSM uses a unique catalytic formulation technology, in which the active group The water in the concrete will catalyze the formation of a large amount of insoluble The tendrils and crystals of water, filling the concrete, make The interior is more dense。 |

Calcium capture and recrystallization cycle technique The active components in BSM can be accurately captured in the concrete Chemical complexation of free CA2+ occurs, resulting in water soluble and Unstable calcium complexes, which are structurally empty with water Diffuse in the gap and encounter a more active hydration potential, live The sexual substance is immediately replaced, and calcium is replaced with a more stable form Crystals to fill the pores and cracks in the structure。Active substance The re-formation of free radicals continues with the infiltration of water into the concrete The concrete structure migrates internally, this process is repeated, and the crystal In the product there are more and more structural defects, so that the interior gradually The reaction forms a tightly bonded impermeable body, thus ascending The overall impermeability of concrete and waterproof, re-entrusts concrete to self Healing power。 |

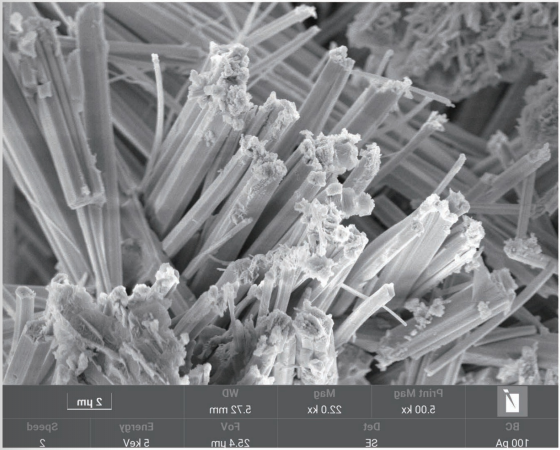

Unique multi-silicon crystal optimization technology

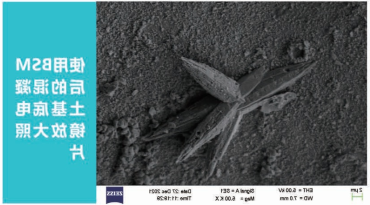

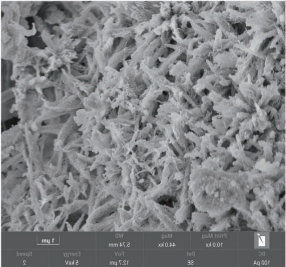

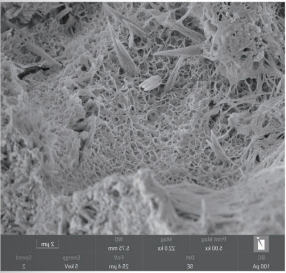

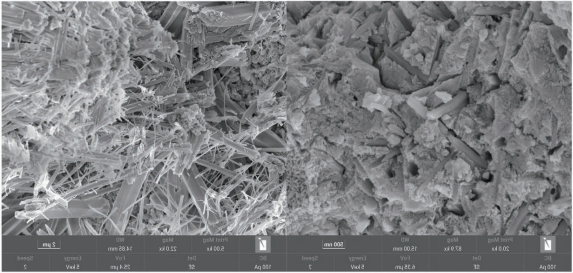

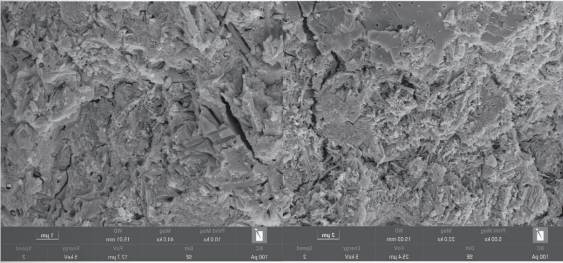

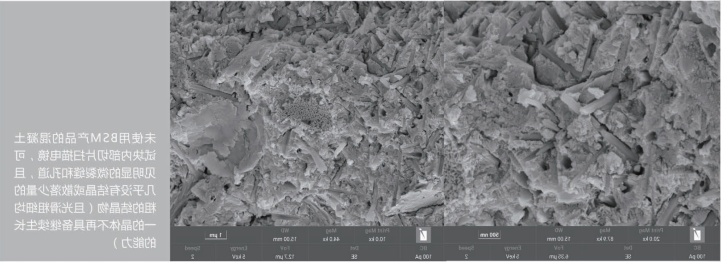

The active silicones contained in BSM can directly participate in the original hydration process of the gelling material and greatly improve the hydration product shape of the gelling material

The appearance, from the original large scattered rods, generates a large number of dense needle-like crystals, which can better plug micro-pores and micro-cracks。左

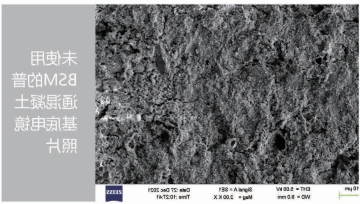

In the picture of the ordinary concrete without mixing, it can be seen that the hydration products such as ettringite generated inside are scattered large rod-like bodies, and the concrete remains obvious

The pores and cracks;The figure on the right shows the shape of the hydration product after adding the star dense needle. After the reaction optimization, the gel holes inside the concrete can be reduced to fine

The micropores are effectively filled to further enhance the compactness。

Sem comparison of internal sections of concrete without and with BSM products

|

|

|

|

4 Core values -

(1)BSM can provide the best concrete durability solutions

BSM can effectively resist the four main factors that affect the failure of concrete structures

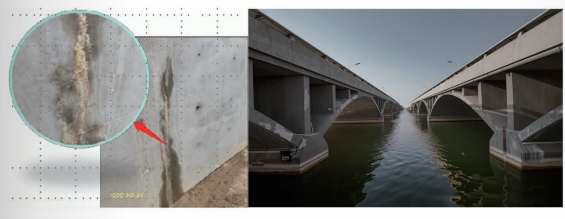

Concrete is the most widely used building material in the world, which enables cities around the world to move from a planar society to a modern three-dimensional society。Concrete is a kind of porous, crack prone, hard solid material。Water-soluble chemicals penetrate into concrete through surface holes, tiny cracks and capillary channels, causing extensive deterioration of concrete and erosion of internal steel bars。

4 Core values -

(2)BSM can extend the service life of concrete by 60 years

The latest research shows:

For a long time, the strength index of concrete structure is the focus of engineers。However, in recent years, the durability of concrete structures has become an important focus。Research, testing and engineering practice show that it is difficult to produce real high-durability concrete only by controlling the optimal water/ash ratio, adding cementing materials to improve strength, increasing the amount of cement and adding air entraining agents。

Professor PLANK, Technical University of Munich, Germany:

The durability improvement of ordinary concrete with BSM self-healing impermeability agent has been studied for many years,The test items include: concrete compressive strength, dry shrinkage, impermeability, sulfate resistance, chloride ion diffusion, freeze-thaw cycle resistance, crack self-healing ability, crystal formation microscopic detection, etc。According to the test data and the expected service life of concrete (Fick's law), the service life of concrete after adding BSM can be extended by 60 years (the years before the corrosion comes into contact with the steel bar).。

The test results show that: after adding BSM self-healing impermeability agent.The durability index of concrete has been greatly improved, and there is no need to add additional silica powder, steel rust inhibitor, air entraining agent, etc.

4 Core values -(3)BSM creates high-quality and durable concrete

How does BSM self-healing impermeability improve many aspects of concrete performance and durability?

Permeability is a key factor affecting the durability of concrete

Water, carbon dioxide, chlorides, sulfates and other potentially harmful substances damage concrete through infiltration。BSM self-healing anti-seepage agent can effectively reduce the penetration of harmful substances and improve the durability of concrete。

1.Permeability coefficient

The optimal water/ash ratio is a key factor in the overall performance of concrete, and permeability is the key to the durability of concrete: reducing permeability means increasing durability。BSM reduces shrinkage cracks and seals fine cracks。BSM can always be repaired during the entire service life of concrete structures.4- 10 mm wide crack。According to the data provided by the European International Concrete Association (CEB) on (anti-seepage admixtures that can withstand hydrostatic pressure), self-healing anti-seepage agents can reduce the permeability of concrete by more than 70%。

2.Reinforcement corrosion

Corrosion of steel bars is an electrochemical reaction caused by the electric potential difference between steel bars and the surrounding concrete structure。Corrosion of steel bars caused by chloride ions is an important factor affecting the durability of concrete。Concrete structures with BSM301 have been tested for chloride rapid penetration (according to ASTM C 1202 and AASHTOT-277), showing a significant reduction in permeability。

3.Self-healing ability

BSM301 is a hydrophilic product. Under the action of water, it reacts with minerals in concrete to form crystals, fill cracks and pores, and give concrete structures the ability to repair themselves。Whenever water is present in the concrete structure, BSM301 is reactivated to form new crystals to repair and plug newly formed porous cracks or pores。

4.Dongrong circulation ability

The freeze-thaw cycle in cold climates is the main factor that causes the deterioration of exposed concrete structures (Bridges, roads, etc.)。 The water inside the concrete freezes to cause volume expansion, and the expansion force causes cracks in the structure: after thawing, the water penetrates deeper into the concrete along the new cracks, and when the cracks are frozen again, the cracks will further expand and deepen, causing the damage cycle。Concrete specimens with BSM301 added showed a 90% reduction in length variation during freeze-thaw cycles。

5.Compressive strength

According to the strength test results of various concrete, BSM301 can increase the compressive strength of concrete by 5%-15%。

6.Acid corrosion resistance

Some projects face the danger of disintegration and failure of concrete structures under the erosion of acid substances。BSM301 provides protection for concrete structures against chemical attack (PH 3-11) and is the preferred and widely used product for projects such as wastewater treatment plants, waste incineration power plants and petrochemical industries。

7.Inhibition of alkali-silicic acid reaction

The gel of alkali silicate will expand in contact with water, resulting in a large expansion stress inside the concrete, resulting in cracking and disintegration of the concrete。Reaction conditions: (1) high moisture content in the concrete structure, (2) there is too much alkaline component or other sources of alkali substances in the cement, (3) there is active alkali reaction component in the aggregate。BSM301 removes moisture from the concrete, thereby preventing the alkali-silicic acid reaction。

8.Sulfate attack

Sulfate erosion is mainly caused by the infiltration of aqueous solution containing sulfate into the concrete, triggering a chemical reaction inside the concrete, resulting in changes in the microstructure of the concrete, including: a large number of cracks appear, the bond failure between the cement slurry and the aggregate, resulting in volume expansion, resulting in an increase in internal expansion force。Extensive testing proved that concrete specimens with BSM301 added to the product were soaked in sodium sulfate solution for a long time and did not show any expansion change in length and size。Untreated concrete specimens soaked in the same sodium sulfate solution showed obvious changes in length and size, and even disintegrated due to expansion。

9.Carbonization reaction

When carbon dioxide reacts with calcium hydroxide in the concrete to form calcium carbonate, carbon dioxide is diluted into carbonic acid, eroding the concrete and reducing the alkalinity, BSM301 closes the capillary channels and cracks, prevents the carbonization reaction of the concrete, and protects the embedded steel bars。

4 Core Values -(4)BSM provides an important solution for enhancing the waterproofing and durability of precast concrete components

| BSM had no effect on the performance of the mixture Water consumption: Water for addition of BSM self-healing impermeability agent There are no additional requirements for quantity。 Working performance: Tests show that the addition of BSM does not shadow Sound concrete performance。 Setting time;The adjustment method is the same as that of ordinary concrete。 |

Application of shotcrete |

|

| Application of precast concrete BSM self-healing impermeability agent can be prepared for precast concrete members An important solution for water resistance and increased durability。 For example: precast pipe gallery, precast concrete storage tank, precast ground Iron pipe, underground water tank。Add directly at the prefabricated parts factory It can save time and cost, and ensure the quality of the finished product。 |

Applications of other types of concrete BSM self-healing impermeable agent can be applied for permanent protection and protection All types of concrete that increase the durability of buildings: Underwater pouring concrete, self-compacting concrete, large volume Concrete, high temperature concrete, large volume fly ash coagulation Soil, water, Marine, railway concrete。 |

Method of using BSM self-healing impermeability agent

|

|

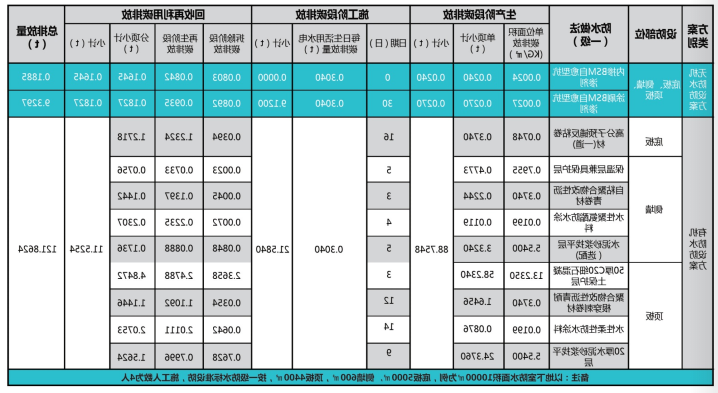

| BSM self-healing impermeable agent A.Dosage: dosage should be 0 of the cement dosage.8% - 2.0%。根据 Extensive engineering practice and experimental analysis: coagulation with strength classes below C60 Soil, the general dosage of BSM301 should be 3 . 0kg 1 m, such as mining Use Portland cement or ordinary Portland cement, according to the amount of cement in the concrete Calculated at 300kg/m, the added amount of BSM301 is the amount of cement 1。0 %。The dosage of BSM301 should depend on the importance of the building, Reasonable selection of factors such as structural thickness and position, environmental effect and construction conditions 择。(Note: Due to the active catalytic substance in BSM self-healing impermeability It mainly reacts with calcium silicate to form silicate hydrate, and then coagulates Plugging occurs in soil micropores and capillaries, acting as precipitates。所以 The content of calcium silicate in different kinds of cement is quite different。According to our country 国情。When different kinds of cement are used, the dosage of BSM301 should be tested To verify;The waterproof concrete design mixed with BSM301 should not be set up Flat and protective layers。) |

BSM self-healing impermeability (external application) A.Brush or spray construction: (Brush: material/water ratio of 5:2。Spray: material/water The ratio is 2:1) Add water in proportion to the mixture until it becomes a paste。Wait 10 minutes Stir evenly until the powder is completely free of particles。According to different base and construction now Field conditions, the ratio of material to water can be adjusted, generally does not affect the effect of waterproof and impermeability 果。The amount of construction is 0.8-1.8KG/ nt, coating thickness is 1.0+0.2mm. Process: After the second layer is dry and solid, the second layer is coated The direction should be perpendicular to the direction of the first layer。To prevent cracks on the surface of the coating Seam, powder, waterproof coating should be kept wet, after the completion of the construction with spray water The coating is sprayed for maintenance, which needs to be sprayed 2-4 times a day, and needs to be increased if the day is hot and dry The number of sprays。It must be protected from rain and frost within two days after construction。Long-term flooding The application in the environment。The waterproof layer should be solidified for at least 14 days before storing water。 B.Dry skimming process: the process is divided into first and after skimming。First spread construction in concrete pouring Before, the powder is evenly spread on the concrete cushion;After scattered construction in concrete After pouring, before the initial setting, evenly spread the powder on the concrete surface and press it to In the concrete surface layer, the amount of material should not be less than 1.5KG/m. |

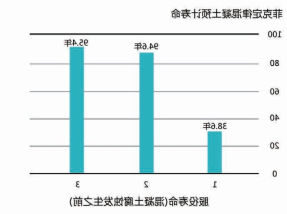

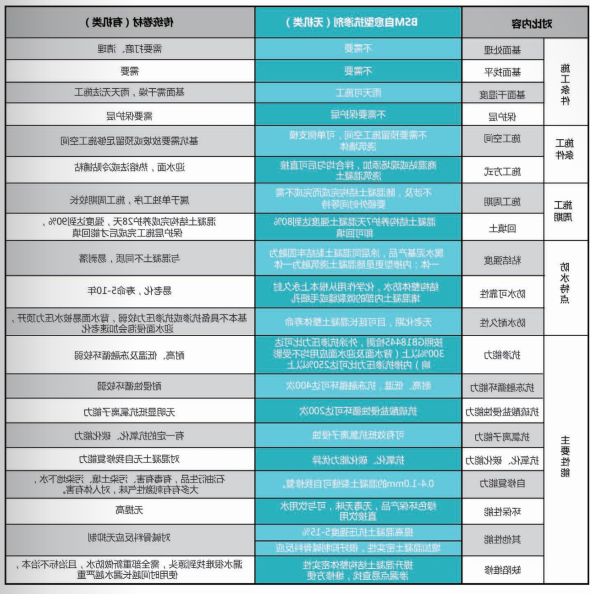

Comparison of technical performance of BSM self-healing impermeability and foreign brands

Comparison of BSM self-healing impermeability and traditional coil

Comparison of carbon emission of BSM inorganic waterproofing scheme and traditional organic waterproofing scheme

In September 2020, China proposed the "double carbon" strategic goal, waterproof industry as an important part of the construction industry, in order to implement the "double carbon" goal, its future will fit the "double carbon" policy, the pursuit of green low-carbon sustainable development, with the lowest carbon method to achieve the goal of water leakage。Compared to organic waterproof materials,Inorganic waterproof materials have obvious carbon saving and emission reduction advantages in material production and processing, on-site construction operations, recycling and recycling (carbon emission reduction rate of more than 90%). , It can effectively reduce the carbon emission of engineering projects,It is possible to "achieve the goal of no water leakage with the lowest carbon method"。

Multison Holdings Group

Service Hotline:0531-89731661

Fax number:0531-82988289

Address: No.67, Sunshine New Road, Shizhong District, Jinan City, Shandong Province

13 / F, Block C, Eurasia Grand Museum

Enterprise Email: zhongsen@ytxdh.com

Factory address: Shandong Province Jinan City Changqing District Gushan Town industrial Road north 2 building

Factory address: West Yongan Road, Litang Town, Binyang County, Guangxi

Wechat interaction

Wechat interaction

Copyright © 2022 Shandong Zhongsen Technology Co., LTD. All Rights Reserved. Lu ICP prepared 13023259-1 Website construction:Power of Chinese enterprises 济南 SEO tag

0531-89731661

0531-89731661

Online message

Online message